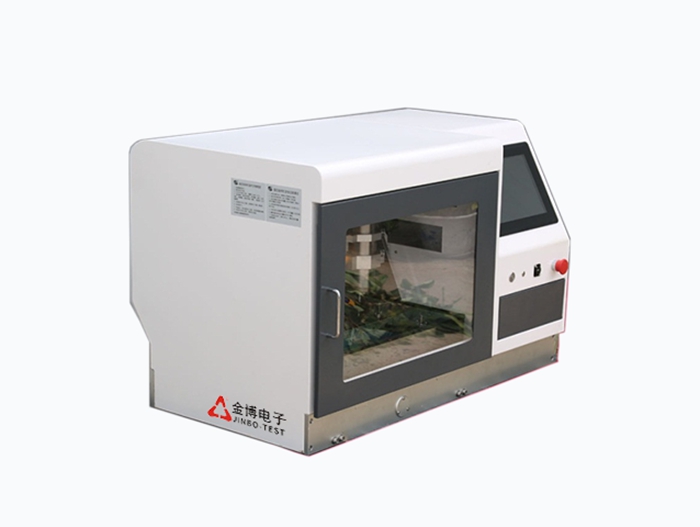

CNC universal prototype

First, overview

The WZY-4030 CNC universal prototype adopts CNC technology, controls the three-axis linkage system through the program controller, drives the XYZ axis motor and is supplemented by the high-speed spindle motor to form a high-precision milling machine system, and realizes the spline cutting of non-metallic plate, dumbbell type sample milling and impact notch milling functions.

First of all, the shape of the sample it makes is not limited by the machine, as long as the program is provided, you can make samples of various shapes, bar, dumbbell type, round, various irregular graphics, etc., unlike the traditional universal prototype can only make bar, dumbbell type sample, and can only make dumbbell type sample corresponding to the template. Secondly, its accuracy is very high, whether it is cutting spline or milling dumbbell, its maximum processing error is only 0.05mm. Again, the basic is not subject to the sample shape line system, as long as it can be clamped to the platform, it can be processed, such as you can directly cut dumbbell sample from a large plate, cut the spline from any position of the plate, milling the spline that does not meet the size requirements.

When the machine is used, if you cut a simple rectangular non-standard spline, you can use manual cutting method; If cutting dumbbell spline or other standard spline, the company provides common standard spline processing program, can be processed directly from the controller; For users to process special shape sample needs, the company can provide programming services.

This machine can be expanded in addition to sample processing more processing functions.

Second, the main technical parameters:

1, maximum milling length: 400mm (without dust cover),300mm(with dust cover)

2, the maximum milling width: 300mm

3, the maximum milling thickness: 20mm

4, height space: 100mm

5, spindle motor speed: 24000r/min

6, control mode: manual control, program control

7, the provider: covering all the common materials dumbbell sample preparation program, impact spline production program, heat deformation Vica sample production program, notch sample preparation program

8, with water cooling system

Third, software function

- a) dumbbell sample preparation procedure covering all common materials, the corresponding sample preparation can be completed by selecting the corresponding procedure.

- b) Rectangular spline spline making function, suitable for making impact splines, heat deformation splines, Vica splines and other specifications of rectangular samples.

- c) Notch sampling function, multiple samples can be stacked on the platform at the same time processing completed. The machining of notches of different specifications can be achieved by changing the tool.

- d) Plate cutting function, the larger plate for cutting.

- e) Pipe cutting function.

- f) Plane milling and facade milling functions, which are used to process special-shaped materials and parts of materials taken off the whole machine into plates, and then process them into required samples.

Fourth, machine configuration

Number control prototype host one.

Milling cutter for cutting. (includes milling dumbbell type) (cutting sheet, pipe)

Flat milling cutter.

Facade milling cutter.

Notch milling cutter.

冀公网安备 13080502000095号

冀公网安备 13080502000095号